Quick Links

Quick Links

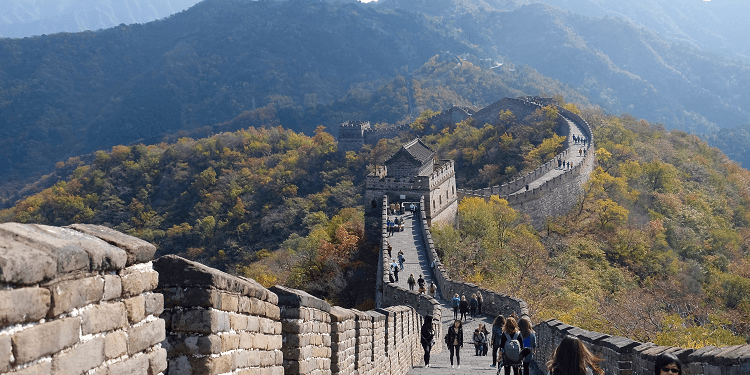

… or Anywhere in Asia

So you’ve decided you want to start sourcing from China to sell products and join the millions of third-party sellers selling on Amazon. You’ve likely watched tons of free videos on how to get started, set your budget for this new business venture, and you’ve started your product sourcing process.

Using tools like AMZ Scout, you’re able to find growing and trending categories, pinpointing a few products that you can private label and sell on Amazon. Maybe you found some product inspiration through Noviland’s Spotlight Products. Your next step is to find a factory, negotiate a killer price, and start selling. Should be easy… Right?

Well, unfortunately it’s not as easy as you think.

Of course there are marketplaces like Alibaba.com and DHGate.com where anyone can start their sourcing journey, but it’s not as easy as just reaching out and locking in a deal for your product. There’s quite a learning curve that comes with sourcing from China and in this article we’ll discuss some best practices and insights that can help drastically shorten that learning curve and potentially help you save thousands.

Prepare Before Sourcing from China

There were over 654 million active consumers across Alibaba’s platforms in just Q1 ‘19 which means suppliers are receiving tons of requests every day to get quotes. Whether you’re dealing with a trade agent or the factory itself on Alibaba, they expect you to be well prepared and won’t provide you high-quality service if you’re not.

The third-party Amazon Seller business model is still something very new to a lot of suppliers and they’re growing to adopt it, but their experience in the past was working with businesses that have project scopes for their products and are typically very experienced in sourcing from China already.

This, of course, puts you at a disadvantage if you haven’t sourced from China in the past, but here are a few things you can do to show them you mean business and streamline the entire sourcing process.

- Have as much technical product specifications as you can.

- Have a plan for how you’d like your products packaged.

- Consider what your target price is and how it ties into your long-term pricing strategy.

- Think about what makes your product a quality one.

We’ll dive into each of these a bit to get you ready to start sourcing.

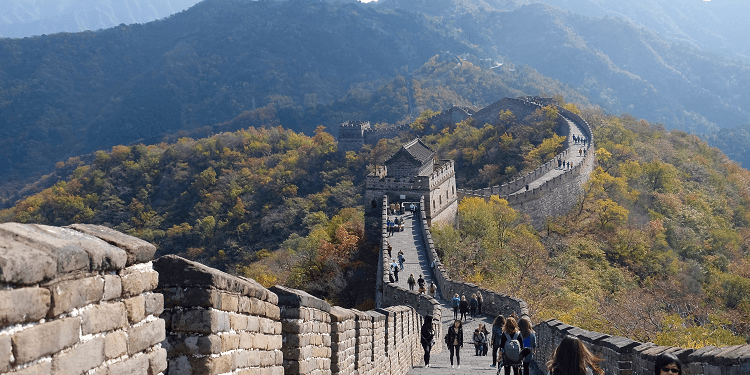

1. Product Specifications

You may think that it should be enough to simply tell the potential supplier the name of the product you’re looking for and they should be able to give you pricing. The issue is that the supplier has likely made dozens of variations of that particular product, so they don’t have a “standard” for the product.

Simply asking them, “Give me whatever you’ve already made.” will lead them to ask, “What do you want?” You may get a catalog from a trade agent if you’re lucky, but if you’re dealing with a factory directly, then that’s highly unlikely.

You want to make sure to include things like:

- Dimensions

- Materials (potential materials they can use)

- Colors (pantone colors if possible)

- Certification requirements

- Customizations (sizing, logos on product, design change, etc.)

- Pictures

- Links to the same (or very similar) products online

Factories often see requests like the first box, but can’t quote accurately unless they have enough product information, like in the second box.

2. Product Packaging

Packaging is often times something that you may want to put off. You don’t even know if this product is going to have a good enough profit margin for you! That doesn’t mean you should hold off on thinking about it. It shouldn’t take you long to come up with something suitable.

Are you okay with getting this product in a polybag? Or is it fragile and will require some expanded polystyrene (EPS), a.k.a. Styrofoam?

- Will you require a full color print box? Or are you okay with it simply being a brown box with your logo on a sticker?

- What are you going to define as a “unit”? Is it 1 product per box? Will it come in a set? Do you want to have 5 products in 1 box?

These are a few simple questions to ask but critical ones when sourcing from China because they impact not only the cost of the product, but also volume and/or weight to estimate shipping.

Make sure your packaging complies with Amazon’s Packaging and Prep requirements and make sure you speak to your supplier about the outer box packaging requirements when the time comes.

Download a Product Packaging Checklist with more detailed packaging specs to consider.

3. Pricing Strategy

Pricing is directly correlated to the quality of the product. One of the biggest complaints Noviland hears from factories about working with new Sellers sourcing from China for the first time is that they’ll say, “I want the best quality at the best price.”

Factories can make a product at various price levels; however, it all comes at a cost. They typically have a wide-span of clients all over the world that have their own definitions of quality.

In doing your product research, you should consider what price you can sell the product for and in doing so, find out the max price you can buy the product for and still be profitable. Keep into account things like FBA Fees and shipping costs to reverse-calculate the most you can pay for the product.

This should help you come up with a long-term pricing strategy to ensure you’re profitable. If you need the product to be $2 FOB to obtain an 80% margin after shipping and FBA fees, then know that you need to EVENTUALLY get the cost down to $2 FOB. Maybe the factory can only sell it for $2.60, but once you hit orders of 5,000 units, they can get it down to $2.

Be wary of pushing your supplier too much when negotiating price. They’ll start finding ways to cut corners to meet your price as they want your business, and that usually comes with compromising quality in ways you can’t see immediately

The factory may not be able to provide this right away, especially when you’re starting off with lower quantities, however once you meet a certain quantity, they may be able to. Be prepared to ask them how many units you need to purchase to get it down to that price. You may need to break even or even lose some money while gaining traction in sales, improving your listing, and marketing your new product.

4. Quality Control Strategy

Once you settle on the price, make sure you get samples and be really critical about the quality of it as this is going to be the quality standard set for larger orders.

Create a list of improvements you’d like made on the sample and ask the factory how much those improvements will affect the price. DO NOT just ask them if they can make those improvements as they’ll likely just reply with “yes” and you’ll be surprised by a price increase down the road.

Aside from the list of improvements, make a list of EXACTLY how you inspected the product sample. You can pull negative reviews from competitors and look for these aspects as that is the best consumer feedback you can possibly get to establish quality control measures.

Provide this QC list to your QC inspector when you place the order so that you make your inspection count. Most QC inspections only look for manufacturing defects, so this list helps you maximize your dollars spent on QC when sourcing from China.

Download an example of how you should create your QC list for your inspector.

Time Spent is Money Saved

This might seem like a lot of work to put in for a product that you don’t even know you can sell at a good margin, but the alternative is spreading this work out over the course of several weeks of back and forth with the supplier.

It will help strengthen your relationship with potential suppliers and cut down the time it takes to source the product in a matter of weeks. They’ll see you as a serious business that knows what they’re doing and not just price shopping.

By taking the extra couple hours in preparing this, you’ll reduce the risks of any quality issues that may arise down the road. Your time is valuable so if you don’t want to do sourcing from China yourself, you can always find a freelancer via FreeeUp and create a template for them using this information.

If you’re tired of dealing with suppliers on marketplaces like Alibaba, you can always check out Noviland. A US-based sourcing company that makes the entire sourcing process simple and streamlined. With a free-to-use software, sourcing from China has never been so easy. You can create a free account today and start sourcing using some of the tips talked about in this article. You’ll have a whole team sourcing on your behalf from a network of pre-vetted factories in Asia.